March 3, 2020

Single-Ply Membrane Roofing: TPO vs EPDM

Written by Gautham Murralitharan –

1- Excellent Reliability

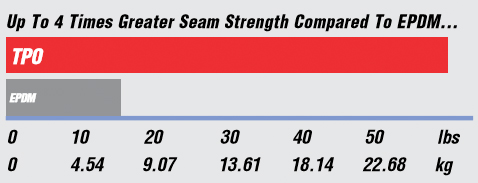

Excellent seam strength as TPO seams are 4 times stronger than taped EPDM and less temperature dependent, which is critical for a long-lasting watertight roofing system.

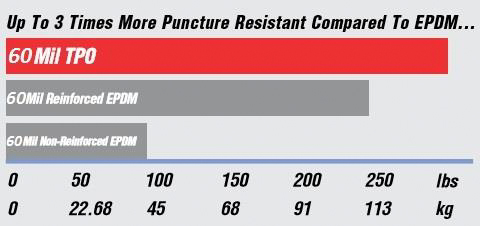

Exceptional puncture resistance, as TPO offers excellent puncture resistance when compared to both non-reinforced and reinforced EPDM of the same thickness.

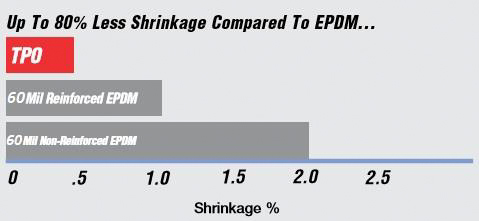

Dimensionally stable, EPDM can shrink up to 2% after installation-the installed roof membrane shrinks by 2 feet (610mm) in a 100 foot (30.5m) run.

2- Easier to Install

TPO installs at least 2 times faster than EPDM.

TPO installs in just 3 steps. EPDM can take up to 12 steps to install-which means more likelihood for error and making repairs to a TPO roof just as simple; just cut a patch and weld in place.

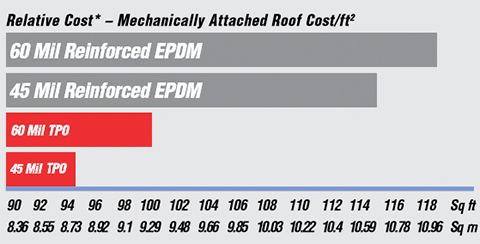

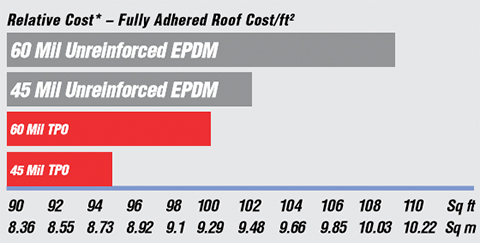

3- Lower-Cost Solution

Choosing the right system is key to minimizing installation, maintenance and repair costs.

TPO membranes come in three styles (including smooth, fleece-back, and self-adhered), with multiple installation options (including mechanically-attached, induction-welding, fully-adhered, and self-adhering). With the most prefabricated accessories available in the industry, TPO gives you maximum design flexibility and allows you to apply the lowest-cost solution to your specific roofing need. The result, TPO systems are less expensive than EPDM on an installed cost basis.

4- Standing/Ponding Water Resistance

A durable roofing system depends on strong seams. TPO’s welded seams are stronger than tapered EPDM seams. By welding the seams, TPO becomes one monolithic membrane across the entire roof. This allows TPO to handle standing/ponding water areas where EPDM systems fail.

5- Energy-Efficient Choice

TPO is the clear winner when it comes to energy efficiency and recyclability.

- On a sunny summer day, a black roof can reach temperatures in excess of 170°F (76.7°C).

- A highly reflective white roof can be as low as 110°F (43.3°C).

- TPO roofs transmit much less solar radiation vs black EPDM into your facility, thereby resulting in energy savings.

- TPO’s highly reflective material helps to reduce overall demand charge on commercial buildings, which accounts to a minimum of 30% of a total electric bill.

6- Weight

Light-weight system reduces load to roof structure and thus reducing damages and losses which may occur due to snow loads, etc. The exposed – membrane systems offer exceptional light weight characteristics over ballasted roof systems which utilize heavy gravel ballast as a major component of the system.

The weight of the new TPO roof system is approximately one (1) lb/s.f. in contrast to the ballasted EPDM roof system which has a weight of appx. (10 -14) lbs /s.f.

Example of a ballasted EPDM rubber roof. Note the abundance of gravel on the surface of the roof making inspections and repairs extremely costly.

7- Solar Ready

TPO is a solar ready roof which allows for future Solar Panel installation while any roof warranties remain valid.

TPO offers Slip Sheets that should be installed below the solar panels rack base. The slip sheets should be a minimum 2″ wider than the contact surface area of the rack base mount on all sides.

Back to Blog